We have talked already about the factors influencing the capture efficiency in a professional kitchen.

Nonetheless, there is one of those we tend to ignore, probably because it is not very “intuitive”.

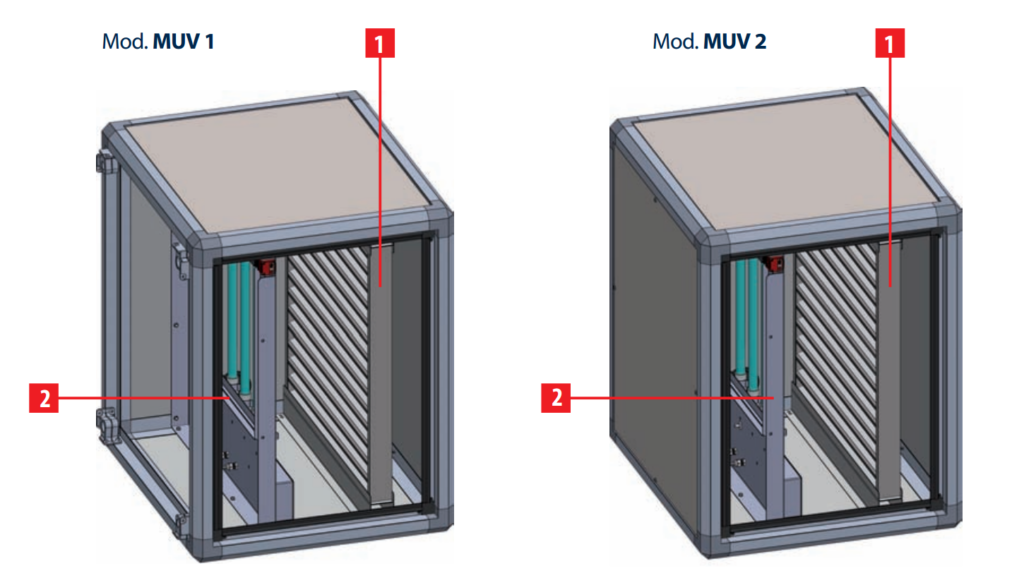

It is called “hood geometry” in scientific literature, and refers to the shape of the hood itself. Just simple as that!

If cubic, round, calendered, with side bulkheads or whatever… All this affects the calculation of the capture efficiency (1).

The internal conformation of steel sheets, for example: it has been demonstrated how containment and extraction can be improved in a hood with a shape that facilitates the creation of natural vortexes (2).

For example: depending on the type of cooking and the thermal plume developed, a central island hood will need greater power than a wall-mounted hood of the same size (3).

Or are you planning to install a central compensating hood? That’s fine, but remember that these will be much more sensitive to air drafts than similar wall-mounted ones (4).

We have already analyzed how and why side bulkheads have a positive effect on extraction capacity in a previous post. Anyway, guess what? It has also been the subject of scientific papers (5).

The baffle filters are very effective, as long as there are at least two! And it is better to place them wisely in a central position, or in any case not at the edges (6).

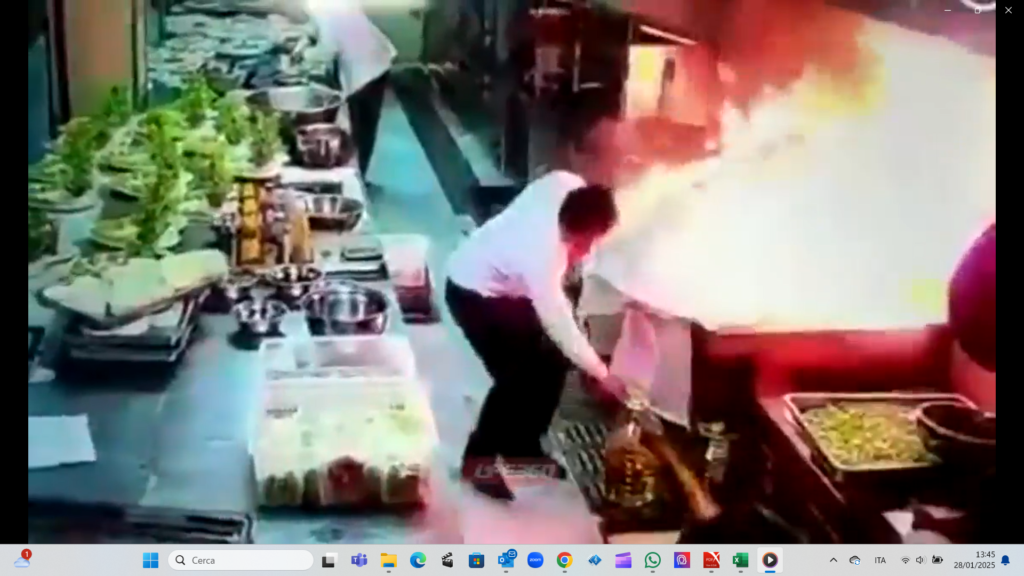

Finally, do you want to open a Chinese restaurant? Well, there is a paper just for you, which analyzes in detail the efficiency of 22 different types of hoods, as well as the configuration of the flues, specifically for traditional Chinese cuisine (7).

Way too much to read, right? You can contact an expert installer… and purchase Aluminox hoods, entirely manufactured in Italy!

Italiano

Italiano