Put some coconut in your kitchen.

Nope… I’m not talking about the edible part of the fruit, be it dried copra, or processed butter, or oil, or whatever.

I’m talking about those carbon filters inside your extractor hood.

The activated carbons, to be more precise, which are used in the air-extraction industry, (also) come from coconut shells.

Let’s break down this amazing revelation…

The woody part of the shell is extracted from the coconut: the endocarp. This is first carbonised and then activated at high temperature (around 1000°C), in the presence of water vapour.

This process creates a lot of micropores which, developing within the entire mass of the coal, give it a high specific surface area.

The extension of the surface area make the carbon ideal for adsorption, i.e. a process through which molecules, liquid or gaseous, are concentrated on a solid surface….

Yada yada yada… You’ve had enough of all this technical stuff talk, right?

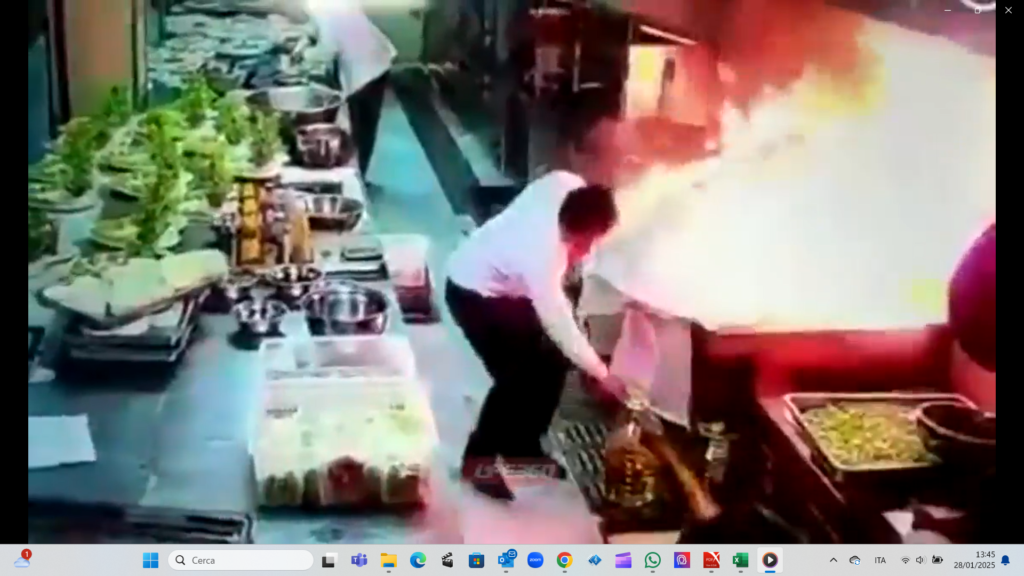

Let’s simply say that the air is induced to pass through these carbon granules, which neutralize odors, capturing (adsorbing) organic molecules, vehicles of impurities, in the cooking fumes.

Just simple as that!

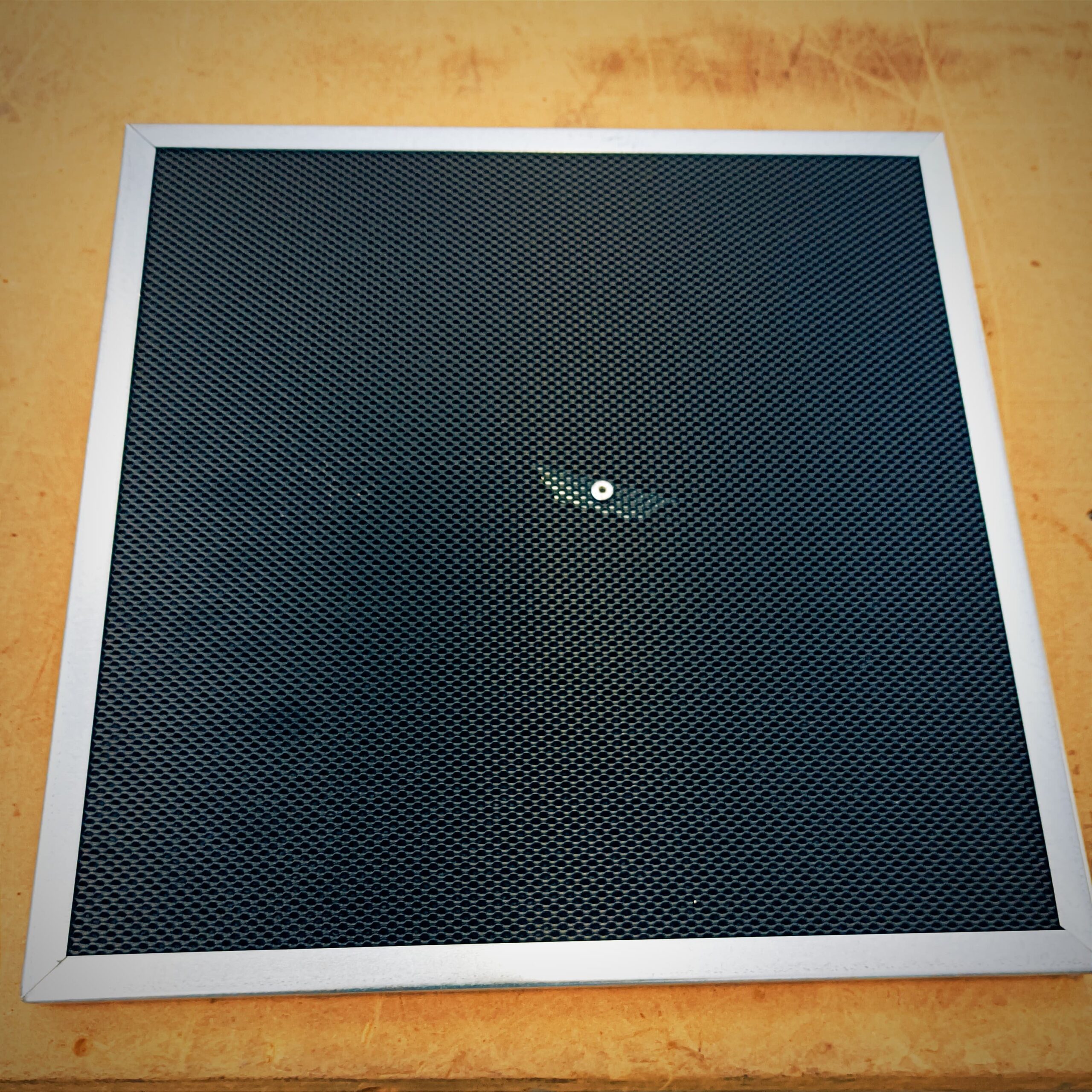

The carbons have a fixed lifespan, after which they must be changed (they are normally enclosed in a mesh filter).

Unfortunately this is their downside: they cannot be regenerated.

Anyhoo… Would you like to know more?

Maybe from someone more knowledgeable than myself (and way less rambling)?

Then contact Aluminox, an Italian company manufacturing extraction hoods for professional catering!

Italiano

Italiano