Installing an induction cooker offers many advantages to a restaurant, including energy savings, easier cleaning, reduced cooking times, and more!

However, one “con” is the ease with which condensation forms.

The induction zone, using electromagnetic energy, heats so that the heat is generated in the pots and/or pans: therefore not heating the surrounding air.

The surfaces surrounding the hob and the hood (and any bulkheads or wall units) will remain cold, especially in the winter seasons. When the (hot) steam comes into contact with these (cold) surfaces, a thermal shock occurs, leading to the formation of small drops of condensation, which can drip or slide down.

The drops of condensation, perhaps harmless at first sight, can gradually lead to some problems, as water is a potential vehicle for germs and bacteria. In addition to “binding” to the grease on the metal filters of the hood and clogging them. Or, even worse, dripping onto the food being prepared.

So how can you prevent this problem?

First of all, turn on the hood 10 minutes in advance and keep it running at all times: it may seem paradoxical, but constant ventilation reduces the incidence of condensation.

Clean the areas where condensation is created as soon as possible.

Use lids to contain the steam.

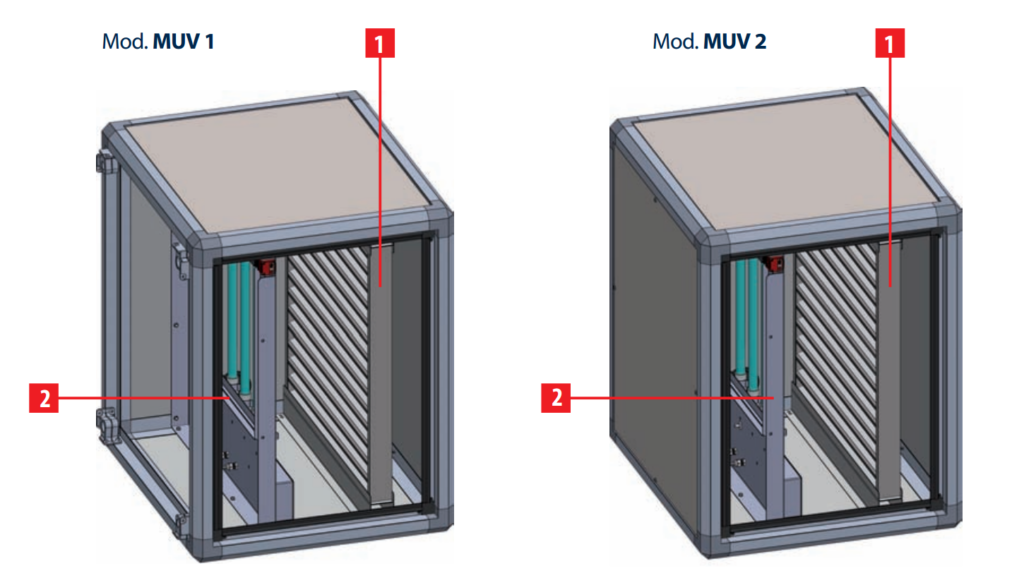

And, last but not least, get a hood with a collection channel and a condensation drain valve!

In fact, the small drops will join the large ones due to a phenomenon called coalescence; the drops, now larger and therefore heavier, fall into a collection area, which can be conveniently emptied using a valve.

By the way: all Aluminox hoods are equipped with a condensation drain valve!

For more information, do not hesitate to contact Aluminox!

Italiano

Italiano