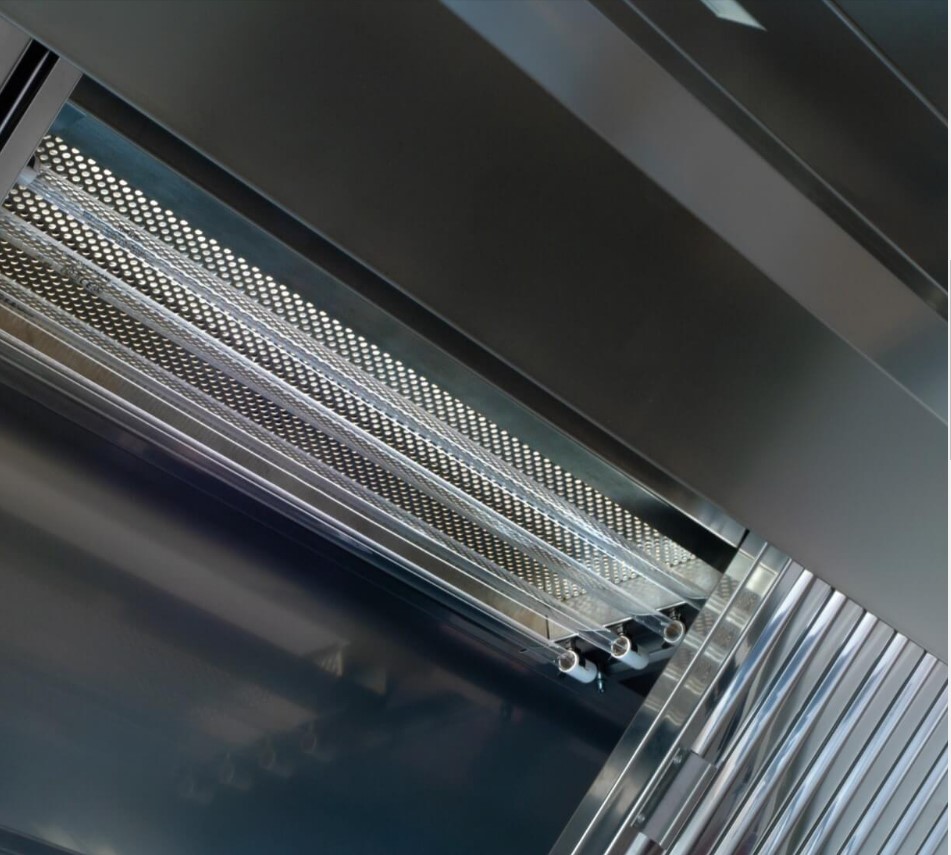

In the air extraction sector for professional catering, there is an ever-increasing use of UV-C lamps.

As we’ve already seen, the lamps directly irradiate the flow of air and fumes with doses of UV-C ultraviolet rays, thus generating ozone which cold oxidizes the fats in the fumes produced. The outcome is a reduction of odours and the fats themselves.

But, specifically, what type of lamps are these?

They are low-pressure, high-output (LPHO) mercury lamps. More precisely, an alloy formed by mercury bonded to other metals called solid mercury amalgam. This regulates the pressure of the mercury gas inside the tube, absorbing or releasing the mercury depending on the fluctuations of the lamp.

The lamps are thus able to emit doses of UV-C rays, 4 to 5 times higher than those of a normal conventional LP lamp, without any “disturbance” that could be caused by high temperatures (up to 120°C), for a total lifespan of 9000 working hours.

All with low electrical consumption (around 90w per lamp), and a host of advantages such as better cleaning operations, drastic reduction of odours, and elimination of cooking fat deposits (and therefore elimination of fire risks due to these).

Would you like to know more? Contact the installer you trust.

And ask him for an Aluminox hood.

Even though he will probably be the one to suggest it to you!

Italiano

Italiano