Let’s talk about Compensating Hoods!

They’re ideal especially for all those catering activities in which there is a large production, and the volumes of air that need to be extracted are high.

They should be in every medium-large kitchen tho!

Yes, perhaps mine’s a bold statement, but there’s a point!

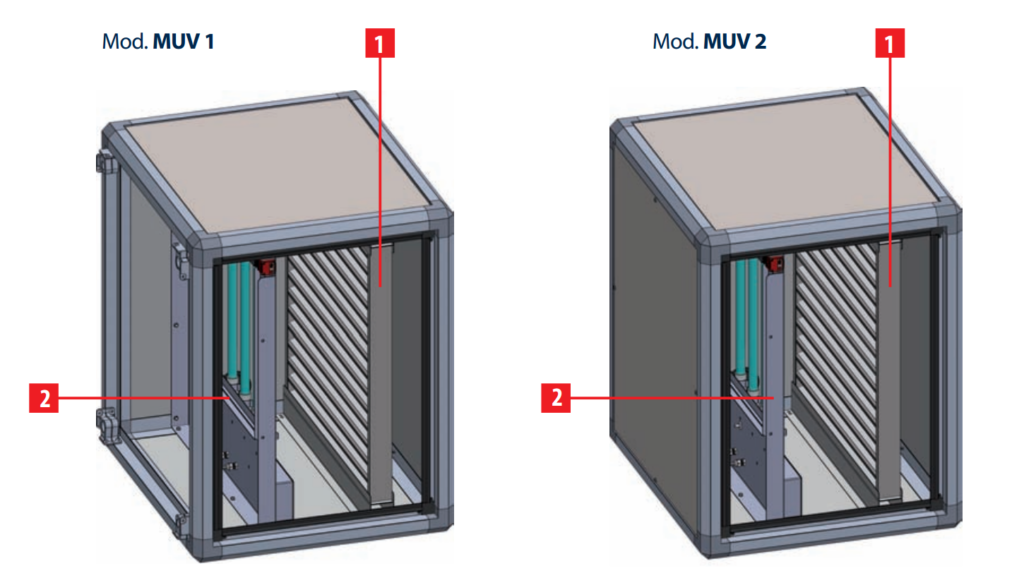

Let’s start first with the definition: a compensation hood is called this because, precisely, it compensates the air it sucks in, introducing make-up air, whether taken from outside or from the kitchen (usually from the area over the hood itself).

Its operation is not overly complicated (at least, to be explained in words!): fresh air is forced inside the hood, then released back into the room. This compensates (the right word!), although not fully, for the cooking fumes sucked in by the hood.

Why not the 100%? There’s a reason!

The room is always kept under negative pressure: this prevents fumes and odours from “escaping”, thus leaving them confined to the kitchen until they are aspirated.

And the pros don’t end there!

The reduced area of the exit channel causes a strong increase in air speed inside the hood (the so-called inductive effect), which drags fumes and odours towards the filters with minimal dispersion.

The extraction of cooking fumes, thus facilitated, avoids having to replace large quantities of air, thus substantially reducing the related air conditioning or heating costs.

To use the appropriate technical jargon: “It reduces the aeraulic deficit created through the two reintegration tunnels“.

I know… hard to understand for those who are not in the sector.

But do you know to whom these things are bread and butter? To the guys at Aluminox: an Italian company manufacturing extractor hoods for professional catering!

If you have any doubts on the subject, just give’em a call!

Italiano

Italiano