Harry Brearley was a metallurgist, born and raised in Sheffield, UK in between XIX and XX century.

He was taught this job by his father when he was only 12 years old. Not something unusual for sure in a city known as the European Capital of the Metallurgy.

During the period immediately before the Great War, Western Countries Governments were spending a huge portion of their budget in military expenses.

During the period immediately before the Great War, Western Countries Governments were spending a huge portion of their budget in military expenses.

Arms’ manufacturing was potentially a big source of income for metal fabrication companies.

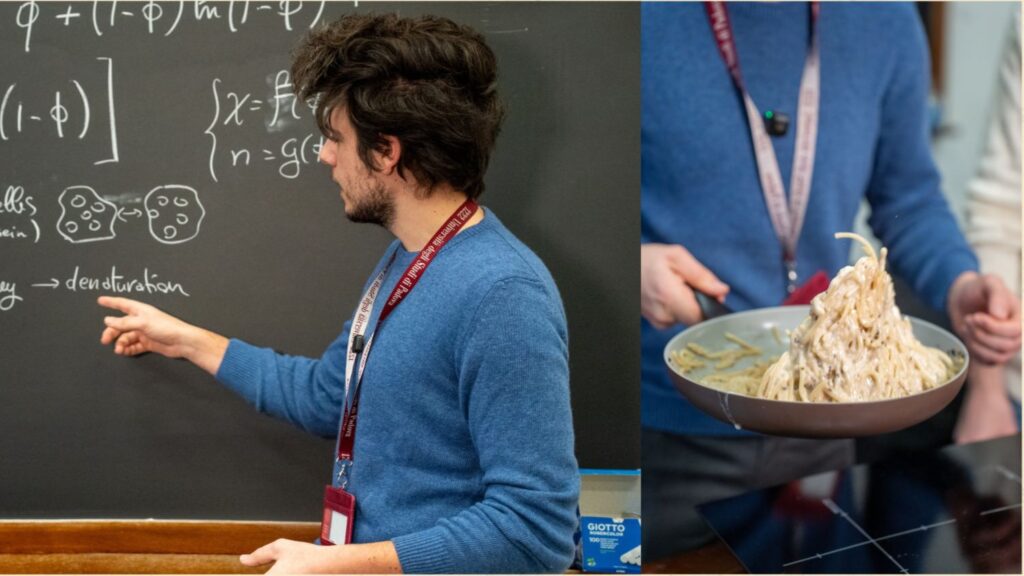

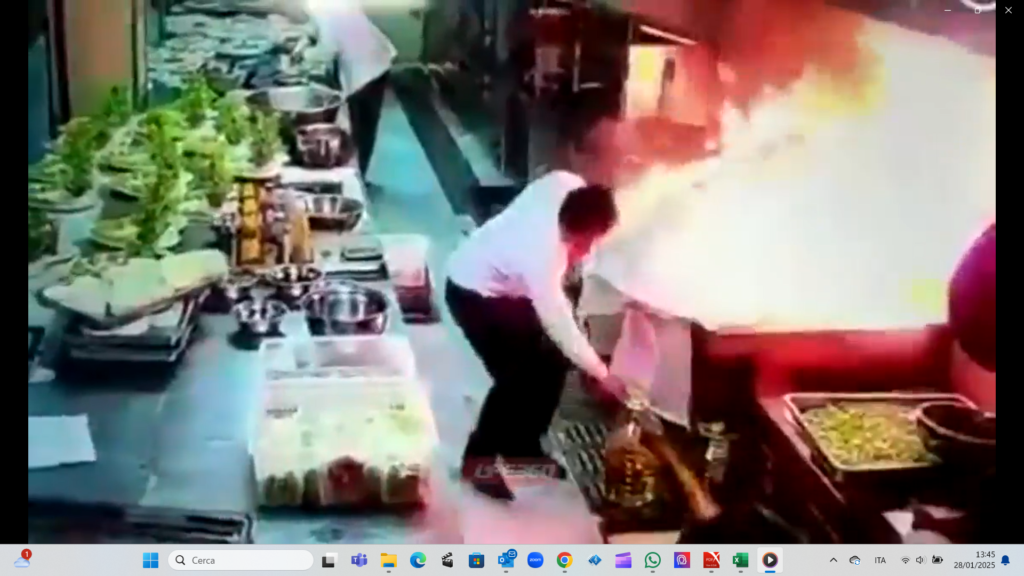

He decided then to research a new material for the weapons’barrels which could resist the erosion due to the high temperatures.

One day, he was amazed at one particular alloy.

When he was about to etch this in a highly corrosive mineral acid, he found out it was overly resistant to many acid solutions.

So, here’s Brearley’s idea: testing it to those acids very common in a kitchen, as such vinegar, tomato, lemon juice, and then make of this a new material for cutlery, pans and all sort of catering equipment.

A new material that could finally avoid unhygienic rusting.

So no sooner said than done.

“Rustless steel” (Brearley was convinced to change its name to “stainless steel” soon) has been, since then, the backbone of the catering equipment business!

Italiano

Italiano