As far as concerns the ventilation in Catering Equipment business, the EU Directive 2009/125/CE, also said ErP (Energy related Products), marked a cornerstone in the Energy Saving field.

The ErP, and following EU regulations, established a new energy efficiency requirement for electric fans, in order to lower carbon-emission and to make it possible to achieve the 20-20-20 energy and climate change objective (at least 20% reduction in CO2 emissions compared to ’90s levels, 20% of the consumed energy coming from renewables and a 20% increase in energy efficiency; to know more about this: http://www.recs.org/glossary/european-20-20-20-targets)

However, 4 more actions can be still done to reduce the energy cost of Ventilation in Catering Equipment Business, that represents from 10 to 15% of the total cost for professional catering preparation.

Training the staff for Hoods maintenance. Despite the EU Laws, and several more Not-EU countries national laws, fix as mandatory the presence of at least one person in charge for the maintenance of the extraction system, that very often ends up as a “formal charge” and, as a consequence, said maintenance becomes unattended. A regular cleaning of the ventilation systems can increase efficiency by as much as 50% compared with systems that are not maintaned – Carbon Trust, Food preparation and Catering: https://www.carbontrust.com/media/138492/j7895_ctv066_food_prep_and_catering_03.pdf

In fact, a greased filter, increases the air flow friction: because of that, the motor will need more energy power to perform.

A scheduled daily cleaning of the filtration system would immediately show up the cost effectiveness of this simple (but often ignored tho) action.

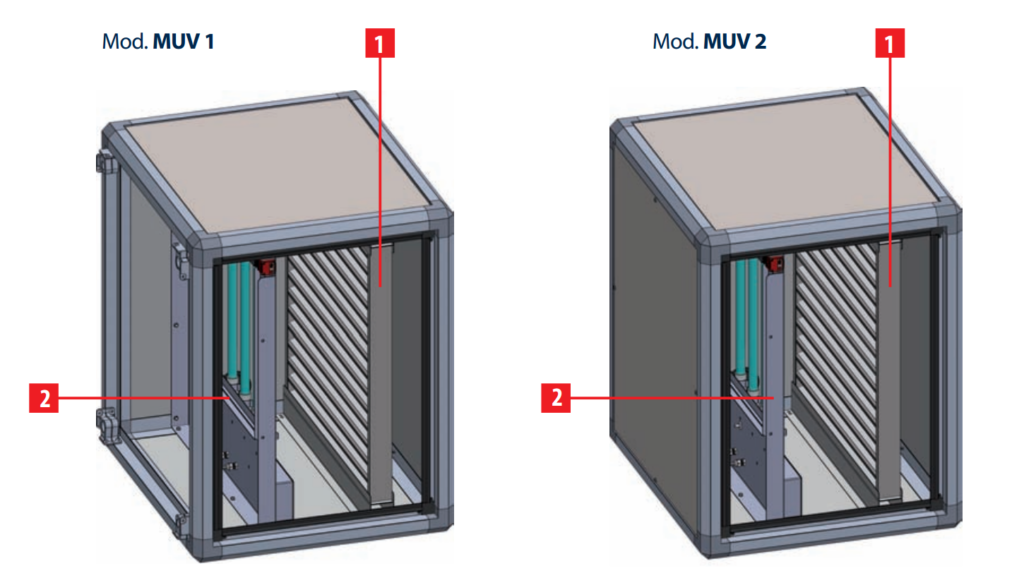

In case there is a Carbon Filter, promptly replacing it when needed would increase the energy efficiency. A new carbon system causes a 250 Pascal of depressurization. That will increase, in a period of 3/6 months, from 350 up to 500 Pascal. As a consequence, the Electric Fan has to work at an higher intensity to overcome this sort of “barrier”. That’s why It is usually suggested to change the carbon filter every 800 hours of work

The height of where the hood is placed plays also an important role in energy saving. In the simplest words as possible: the higher is the Hood located, the higher are the motor performance needed. The minimum height of a hood is established by regional or local laws, and there’s no uniformity even considering one domestic market. The advise is to place it as lower as possible.

Compensation hoods with heat recovery appliances allow to re-use the warm air expelled by catering facilities for heating either (or even both) water or the air inside the room. That would make, during the cold season, way more unexpensive to bring the air at a temperature of 18C or more.

Italiano

Italiano